Exactly How a Silicone Rubber Keypad Can Transform Your Tool's Individual Experience and Longevity

Understanding the Benefits of Using Silicone Rubber Keypads in Modern Electronics

The use of silicone rubber keypads in modern-day electronics offers a compelling instance for their adoption throughout different markets. The discussion does not finish there, as further expedition reveals added factors that might influence the choice to utilize silicone rubber keypads in item design.

Durability and Durability

The resilience of silicone rubber keypads is a specifying feature that improves their allure in contemporary electronic devices. These keypads are engineered to hold up against extensive wear and tear, making them an ideal choice for tools requiring constant use. The inherent flexibility of silicone permits for a considerable lifespan, as the product can endure duplicated compression and contortion without shedding its initial shape or functionality.

In addition, the production process of silicone keypads permits for accurate personalization, allowing the style of complex shapes and tactile feedback features that boost user experience. Consequently, makers can produce durable keypads tailored to certain applications, enhancing their dependability and efficiency in different electronic gadgets. Ultimately, the sturdiness and long life of silicone rubber keypads place them as a favored option in the landscape of modern-day electronics.

Resistance to Environmental Aspects

Silicone rubber keypads are not only identified for their toughness and durability however likewise for their exceptional resistance to ecological elements. This product shows extraordinary performance in a range of challenging problems, including exposure to extreme temperature levels, moisture, and UV radiation. Silicone Rubber Keypad. Silicone rubber preserves its structural stability and performance across a large temperature variety, from -60 ° C to 250 ° C, making it suitable for both interior and outdoor applications

In addition, silicone is inherently immune to water and humidity, protecting against damage from spills or condensation, which is critical for gadgets utilized in humid atmospheres. Its hydrophobic properties make sure that wetness does not compromise the functional effectiveness of the keypad.

Furthermore, silicone rubber's resistance to UV radiation safeguards the keypad from fading and destruction when subjected to sunshine for prolonged durations. This particular is particularly useful for customer electronic devices, automotive controls, and commercial equipment, where extended exposure to the elements is typical.

Customization and Layout Adaptability

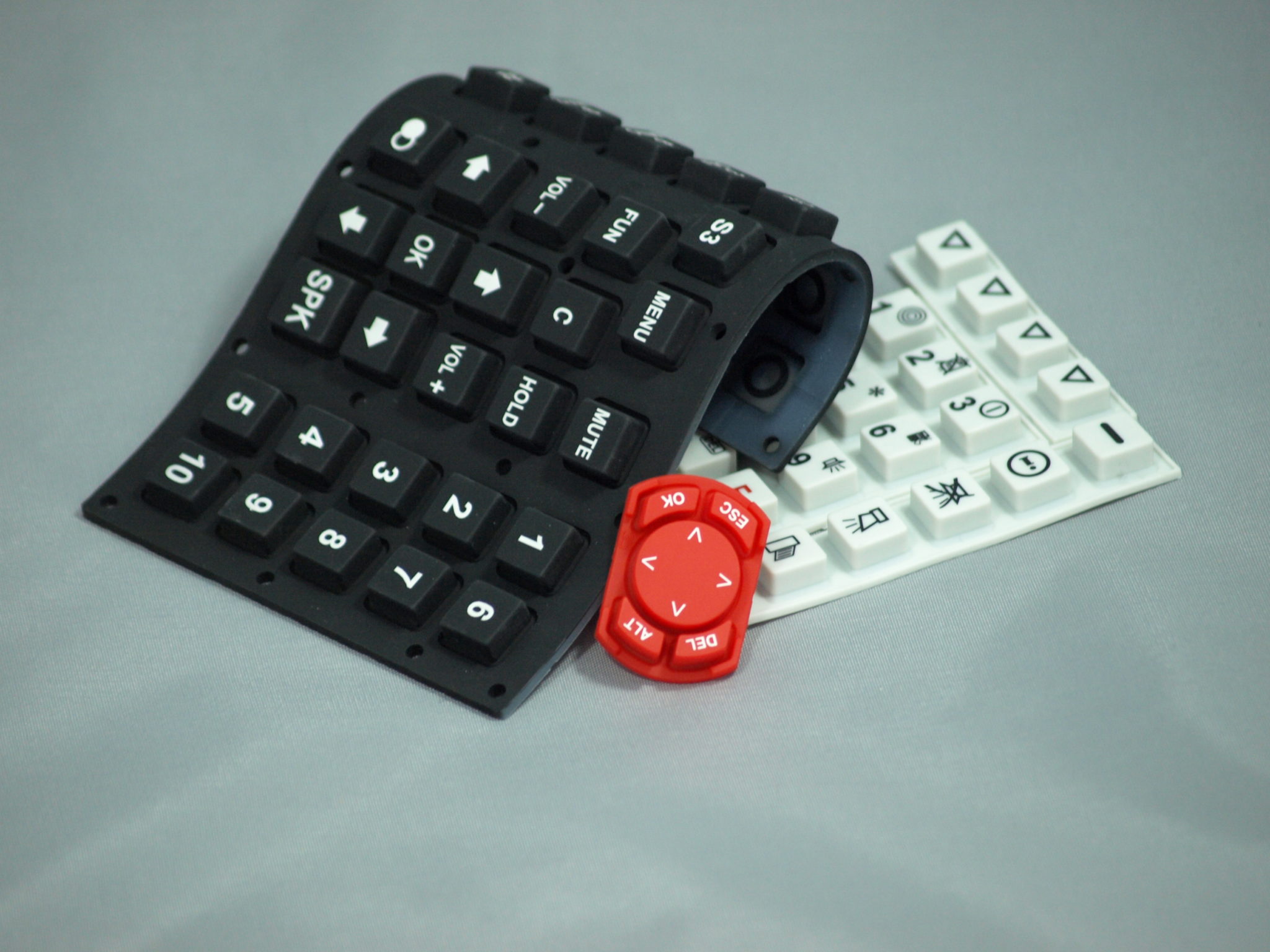

With a vast array of customization alternatives offered, silicone rubber keypads can be customized to satisfy details style demands and aesthetic preferences. Manufacturers can develop keypads in different forms, dimensions, and colors, permitting smooth combination right into diverse digital gadgets. This flexibility indicates that developers can pick from a substantial palette of shades and structures, making sure that the keypad complements the overall product style while preserving brand name identification.

Furthermore, silicone rubber keypads can be formed to include distinct features such as increased or recessed buttons, varying tactile comments, and also backlighting choices. This flexibility not just boosts the aesthetic charm yet also permits for useful differentiation in item offerings.

Inevitably, the modification and design adaptability fundamental in silicone rubber keypads make them an optimal option for modern-day electronic devices, permitting the development of user-friendly, cosmetically pleasing, and functional user interfaces tailored to certain market needs.

Boosted Customer Experience

Enhancing user experience with intuitive style is a crucial advantage of silicone rubber keypads. These keypads are crafted to give tactile feedback, allowing customers to get instant sensory verification upon pushing a button. This feedback is important for making certain accuracy in device operation, which improves overall customer contentment.

The ergonomic style of silicone rubber keypads additionally adds to an enhanced customer experience. They are often shaped to fit the shapes of the fingers, making them comfy to use over expanded durations - Silicone Rubber Keypad. This is particularly advantageous in applications where frequent interaction is needed, such as in medical devices or consumer electronic devices

In addition, silicone rubber keypads can be developed with differing textures and surface coatings, accommodating diverse individual choices and improving use. Their capability to include backlighting and custom-made symbols also permits much better exposure in low-light conditions, boosting ease of access for all users.

Furthermore, the resilience of silicone rubber makes certain that keypads keep their performance and look with time, minimizing the requirement for substitute. This longevity promotes a Check This Out reliable individual experience, as customers can trust that their tools will certainly do consistently throughout their life expectancy.

Cost-Effectiveness and Performance

A considerable advantage of silicone rubber keypads hinges on their cost-effectiveness and efficiency in production. The manufacturing procedure of these keypads typically entails injection molding, which allows for high-volume manufacturing at fairly affordable. This technique not only lowers material waste but additionally improves the assembly procedure, reducing labor expenditures. Consequently, manufacturers can attain a beneficial roi.

In addition, silicone rubber keypads are resilient and immune to wear, which additionally enhances their cost-effectiveness gradually. Their longevity decreases the demand for frequent substitutes, bring about lower general lifecycle prices for businesses and consumers alike.

Furthermore, these keypads can be tailored easily to satisfy details design demands, which includes to their performance in terms of advancement time and sources. Quick prototyping capabilities enable business to bring their items to market faster, offering an one-upmanship in the busy electronics landscape.

Conclusion

In final thought, silicone rubber keypads existing many benefits that make them a recommended choice in modern electronics. Their outstanding longevity and resistance to ecological factors ensure lasting performance. The capacity for personalization and style versatility improves both performance and aesthetic charm. Additionally, the enhanced individual experience coupled with cost-effectiveness adds to their popularity across various applications. Inevitably, silicone rubber keypads stand for a sensible and reliable service for producers aiming to fulfill the needs of contemporary consumer electronics.

The usage of silicone rubber keypads in modern-day electronics offers an engaging case for their fostering across numerous markets.The sturdiness of silicone rubber keypads is a defining attribute that enhances their allure in contemporary electronics. Eventually, the resilience and long life of silicone rubber keypads position them as a recommended option in find the landscape of modern electronics.

In conclusion, silicone rubber keypads present numerous benefits that make them a recommended option in modern-day electronics. Inevitably, silicone rubber keypads represent a sensible and efficient option for manufacturers intending to fulfill the demands of modern customer electronics.